Penn Electric Racing

The Team

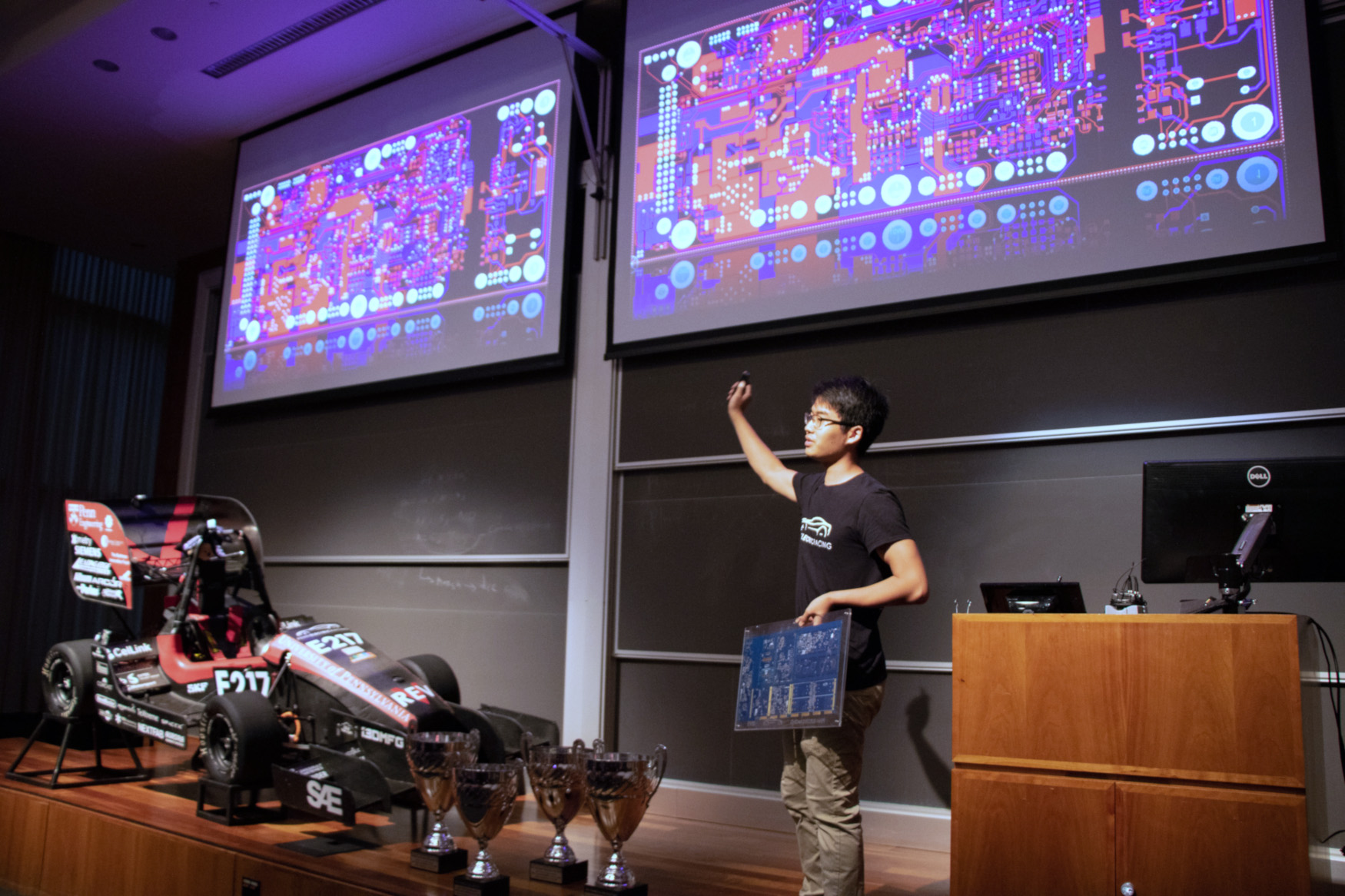

Penn Electric Racing is a student run engineering team that competes in the Formula SAE Electric. We’ve historically built electric racecars that rank top three internationally at competitions such as FSAE Lincoln and have held the record for fastest acceleration time. More information about the team can be found on our website!

Responsibilities

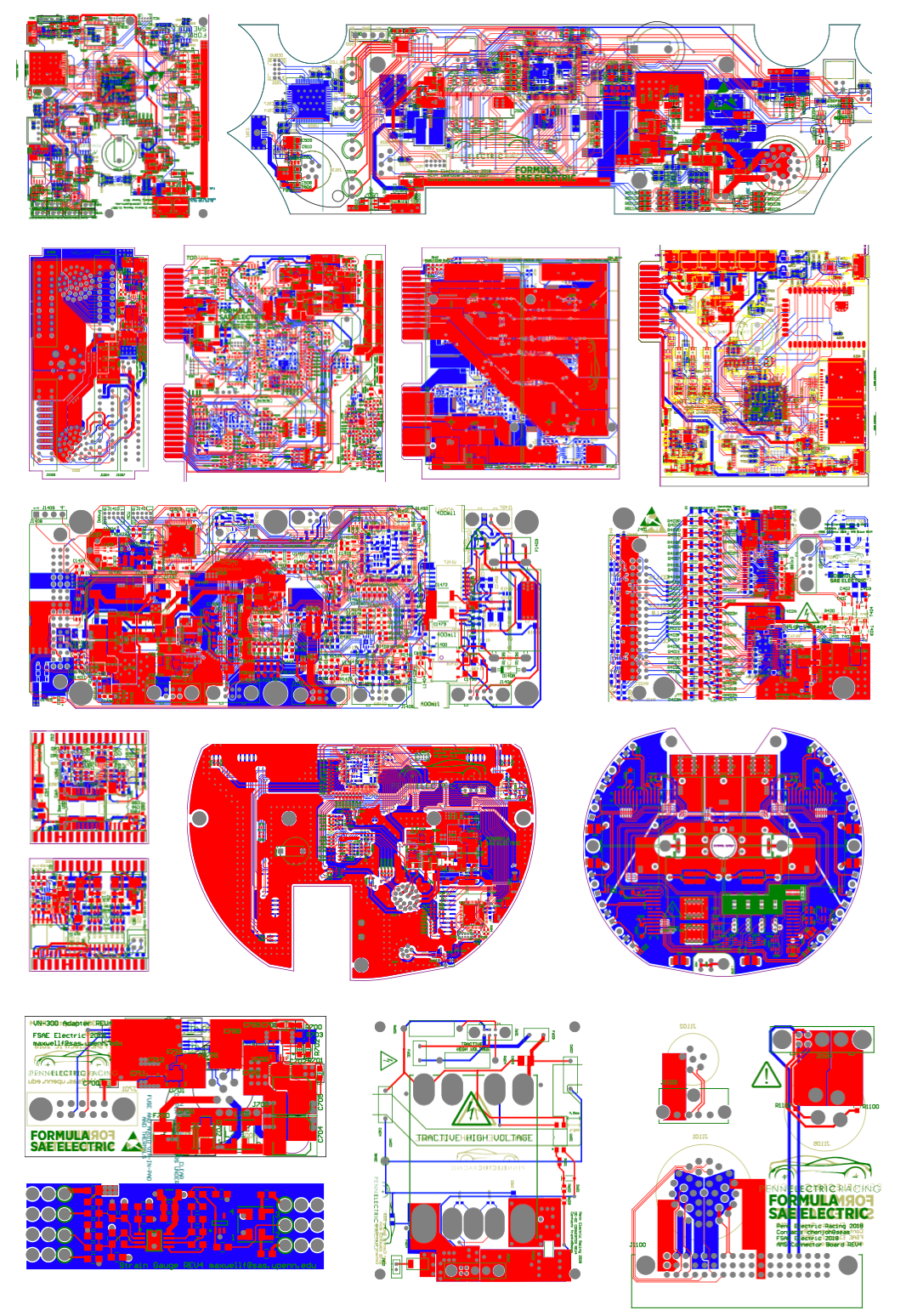

The hardware subteam designs, reviews, and tests about 15 custom four-layer PCBs each year. Our designs include a LCD dashboard, an e-fused power distribution unit, and a powertrain control module.

As the electrical lead, I managed the timelines for and reviewed all of these boards. However, I worked most closely with designing the Battery Management System. More details are included below.

I’ve also fostered team growth by documenting our designs on Confluence, developing a new member curriculum, and speaking recruiting events, such as info sessions or club fairs.

Battery Management System

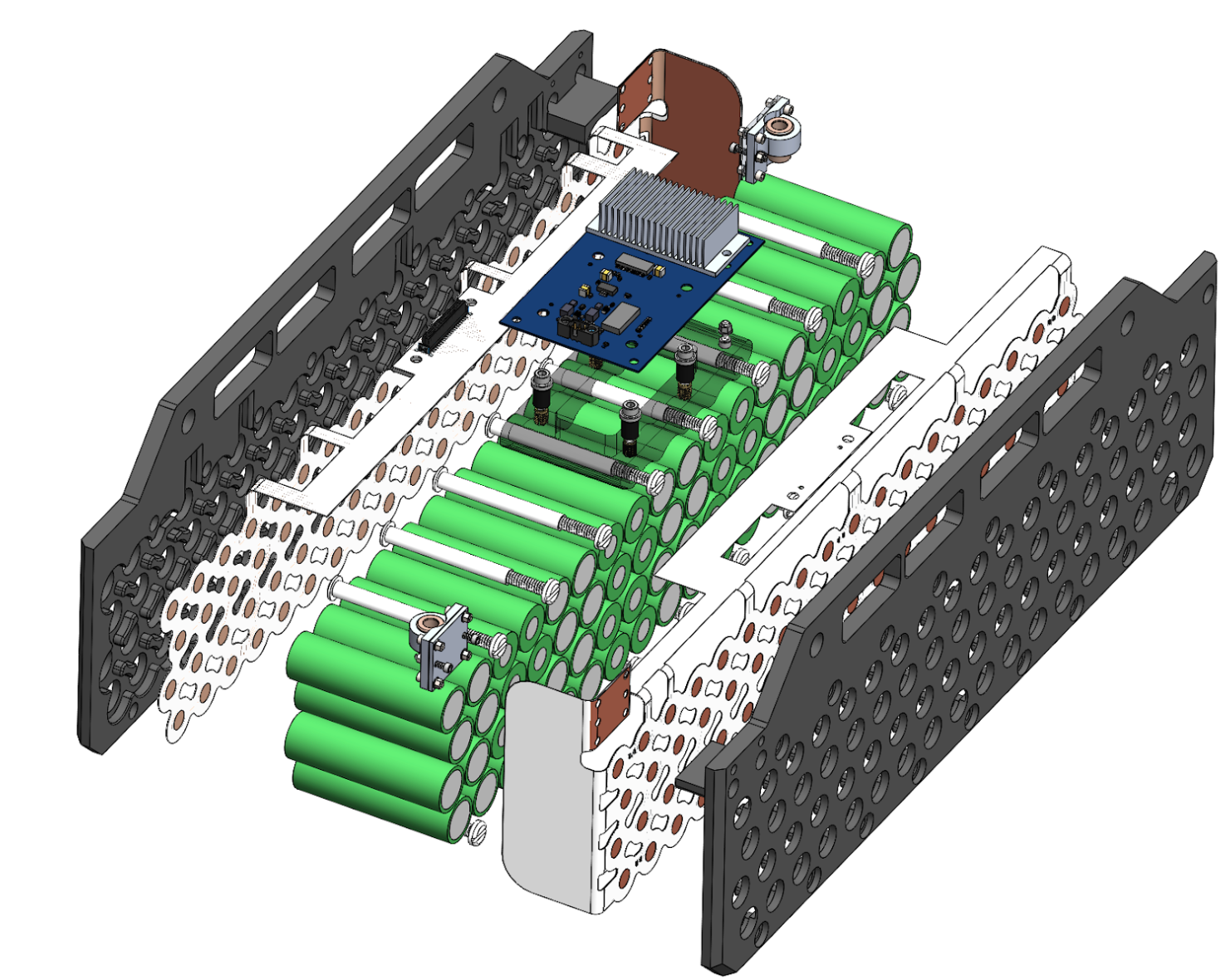

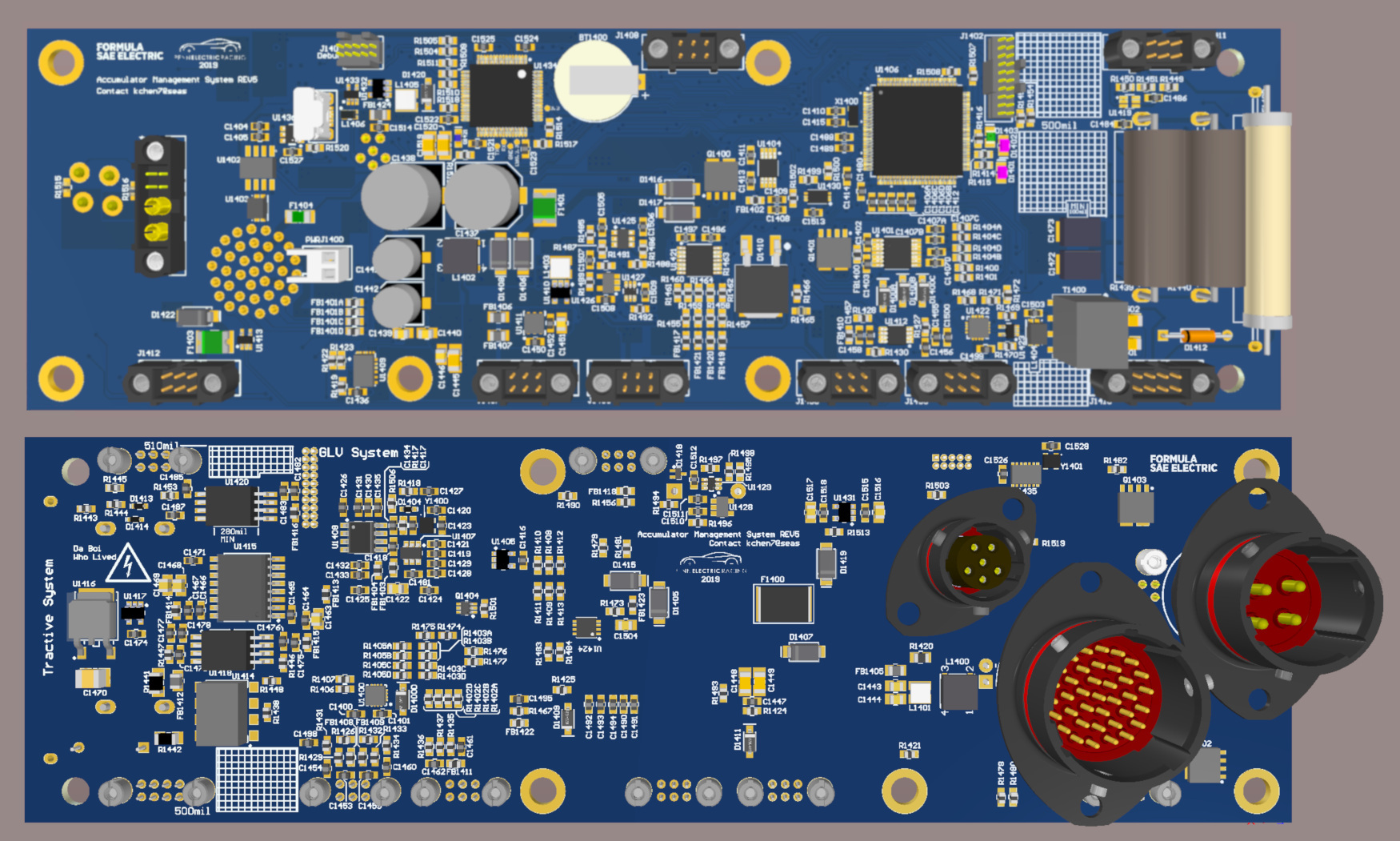

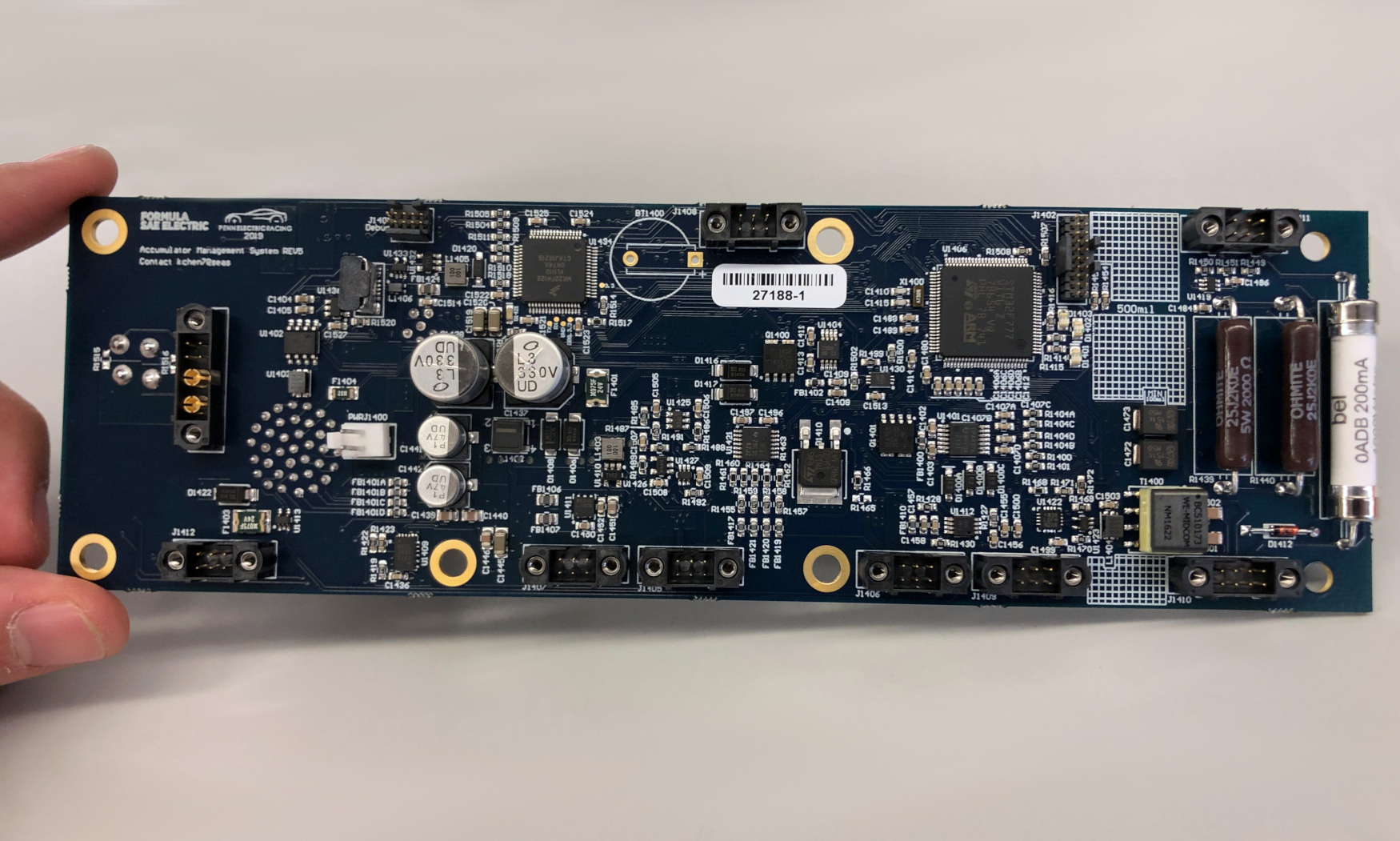

The semi-distributed, battery management system monitors a 300V battery made of 576 lithium ion cells. These cells are connected in a 72s8p configuration and broken up into eight 9s8p substacks. Within each substack, the cells are welded together on a flexible PCB containing fuses, cell taps, and thermistors. A daughter board sits above the substack, connecting to the flexible PCB to measure and balance the voltage of the cells using the LTC6811 battery monitor. The daughter also measures cell temperatures with the thermistors through a mux.

These eight daughter boards are daisy-chained together and communicate with the motherboard through the LTC6820 isoSPI interface. This board also monitors the battery at a macro-level, measuring voltage, power draw, and insulation. It contains a STM32F7 microcontroller that analyzes the data for faults, closing the battery isolation relays only when safe. Finally, the motherboard pre-charges the motor controllers on startup and communicates with the rest of the car using CAN. The CAD and PCB are displayed below.

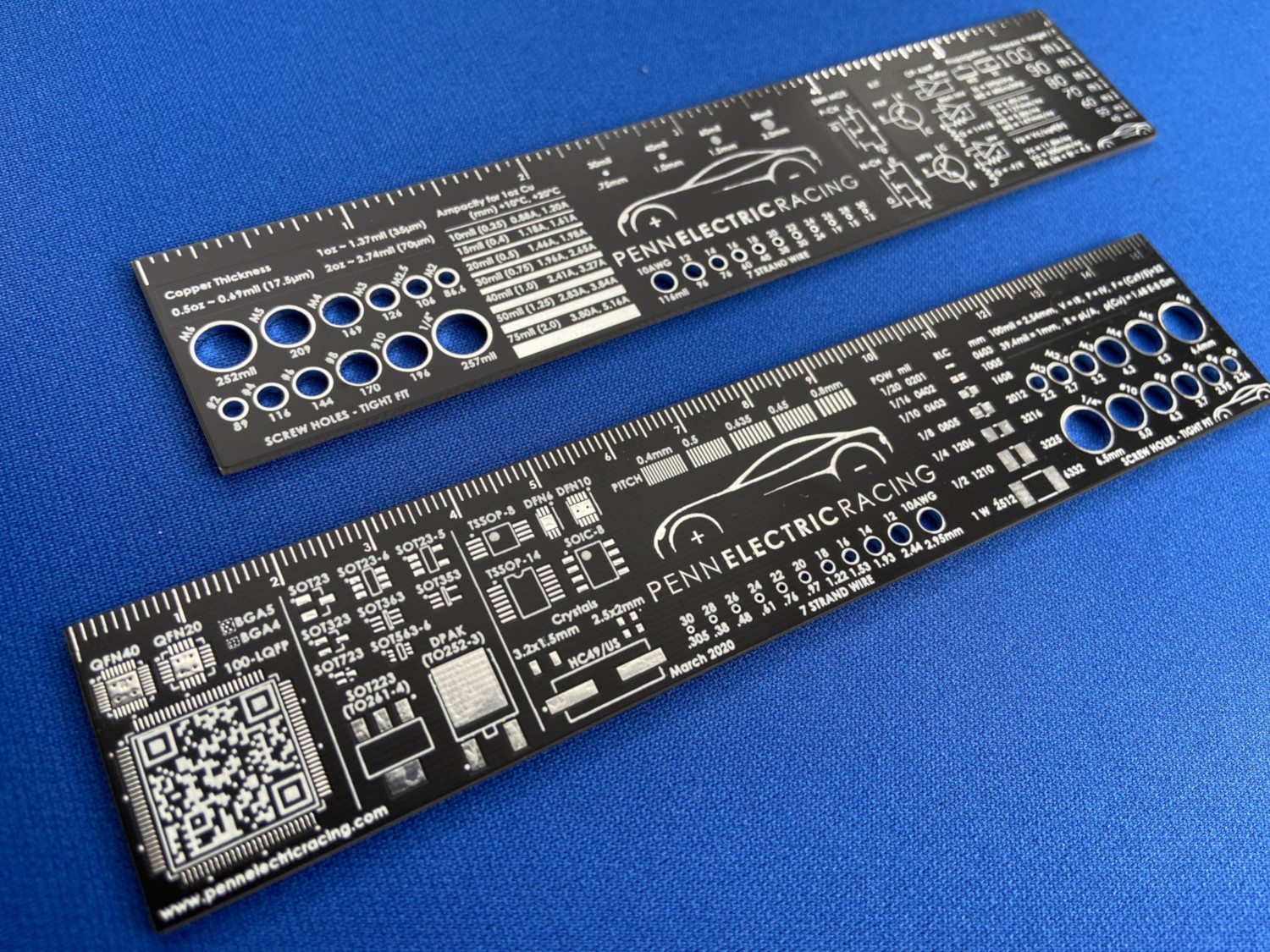

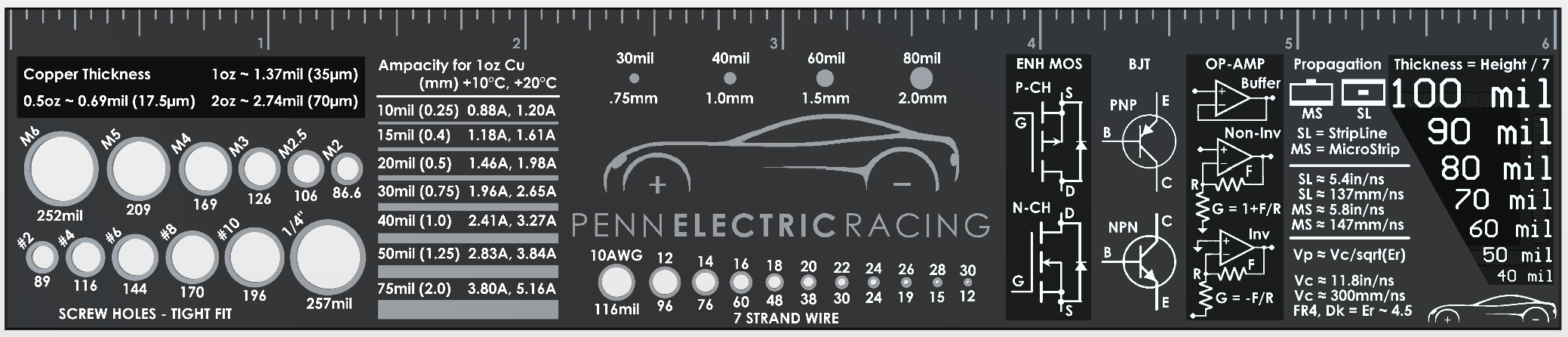

PCB Ruler

Inspired by other PCB rulers such as the ones made by Digi-Key or Nvidia, I decided to design one for Penn Electric Racing to use as merchandise. I opted for a 6” design, rather than 12”, for improved portability. In addition to being merchandise, I wanted the ruler to be a useful resource to members on the hardware team, so it is covered with layout and electrical engineering references:

The PCB was finished with black solder mask and lead-free HASL to match Penn Electric Racing’s colors. The final product is pictured below!